IEEE Spectrum

Singapore’s toilet-to-tap technology has saved the country from shortages—and a large electricity bill

By Sandra Upson

Singapore began its journey to sovereignty with a mighty jolt. The island was still an exotic outpost of the British Empire when World War II delivered the shake-up. Japan’s army was preparing to invade from the Malay Peninsula, and the British forces beat a retreat to Singapore across the one bridge connecting it to the mainland. To thwart the Japanese troops, the Royal Engineers blew up the bridge behind them.

The blast sealed the island’s doom, for it also ruptured a critical pipeline that brought water from Johor, a Malay state. The people of Singapore discovered they had only a few days’ water stored in their meager reservoirs. The island was truly defenseless. The Japanese swiftly repaired the bridge, bicycled across the strait, and claimed victory.

Sixty-eight years later, this port city has both gained territorial independence and managed to bootstrap its way to wealth in spite of a lack of water and energy. And now, against all odds, complete water independence—from both Malaysia and even the weather—is within easy reach. Rather than flushing waste into the sea, the water utility collects the country’s wastewater, cleans it to pristine levels, and returns it to the public supply. Singapore has thus short-circuited the water cycle by reducing it to an island-ringing loop.

At first, no one relished the idea of drinking wastewater. Rejuvenating the waste stream requires electricity to power an intensive cleaning process, and that investment makes the recycled water more expensive than what’s used by cities blessed with nearby freshwater lakes, rivers, and aquifers. But presented with a set of tough choices, Singapore chose water recycling—and so far it has worked admirably.

When Singapore finally separated from Britain and then Malaysia in the 1960s, water was at the top of the agenda. The government negotiated two treaties with its mainland neighbor to guarantee a water supply, at a cost, for the next century.

With a base supply in place, the water utility went looking for more. The agency started with the one resource available to this tropical dollop of land, its ample rainfall—some 237 centimeters a year. It built dams to interrupt the flow of its streams and tiny rivers and built 15 reservoirs to store rain. Such reservoirs are crucial because they stand in for the groundwater that Singapore lacks.

Then the utility did a radical thing. After half a decade of research and tests at a pilot recycling plant, Singapore’s planners unveiled their ultimate strategy for water security. They would force wastewater through filters under high pressure to remove all microbes, viruses, and larger impurities. The utility called its product NEWater, and it called the treatment plant a factory. With great emphasis on its sparkling newness, treated wastewater made its public debut in 2003.

The real work was about to start. One by one, the utility cajoled its customers into accepting the water. Manufacturers wondered what residues the water might leave in their factories, but Harry Seah, the utility’s director of technology and water quality, pointed out that NEWater was cleaner than most drinking water. “At first I had to convince them,” Seah recalls. But soon enough, he had signed on the island’s 12 wafer-fabrication plants and other electronics manufacturers, and the utility laid dedicated pipes to deliver NEWater. Now Systems on Silicon Manufacturing Co., which uses ultrapure water to wash its silicon wafers, champions NEWater. The company calculated that the recycled water’s exceeding purity saves it more than half a million dollars a year, in part by cutting out steps in its internal water-purification process.

Singapore also started priming the public. The prime minister drank a bottle of NEWater at a national festival, and the crowd cheered. The subtext was clear—patriotic Singaporeans drink wastewater. But the rest of Singapore was slower to follow. A parody of a popular nationalist song, “Count on Me, Singapore,” cheerily urged residents to “Drink Our Pee, Singapore.”

The queasy reactions of some Singaporeans didn’t deter the utility, which built four more wastewater treatment plants and is about to increase its NEWater production to 555 megaliters a day. By the end of this year the plants will treat enough sewage to cover nearly a third of Singapore’s water needs.

For now, only a tiny fraction of the drinking supply is NEWater. About 40 ML are blended in with the city-state’s potable water each day, equivalent to 2 percent of consumption. The utility also built a seawater desalination plant that produces 136 ML of water each day, or a bit less than one-tenth of Singapore’s supply. The city-state has all the water it needs. NEWater Taste Test

Three choices: NEWater, bottled water from Malaysia, and a glass filled at the tap. Your correspondent sat down to drink. The NEWater was bland to a fault, like paper made potable. The Malaysian water delivered a cloying aftertaste—a perplexing blend of dryer lint and berries. The drink from the tap, however, was just right.

Nature’s hydrological cycle relies on sunlight to evaporate water, leaving behind salt and other impurities and returning freshwater to Earth in the form of rain and snow. But it can be capricious: Most freshwater evaporates from the oceans, where it rises through the atmosphere and then cools to form clouds. Winds push around the clouds, driving a few of them over land, where they deposit a mere tenth of the world’s precipitation, according to the U.S. Geological Survey. Singapore decided to cut the atmosphere out of the transaction and to replace evaporation with speedier mechanisms—membranes.

Here’s how it works: First, a treatment plant gathers up the city’s used water and separates out the large, easily removable impurities. About 60 percent of the water is released into the sea. The rest gets sent to a NEWater factory. The water enters contaminated with bacteria, viruses, and all sorts of carbon-based particles and emerges cleaner than what flows from just about any tap in the world.

The main tactic of the water trade is to simply push water through tiny holes—the smaller the holes, the fewer the undesirable molecules that can sneak through. The art is to do so without sending the electricity bill skyrocketing or clogging up the tiny holes with grime. Here, the first step is to force the water through a membrane that blocks particles of up to 0.2 micrometers in size, catching most bacteria and protozoa. The membrane looks like a cylinder filled with skinny, hollow tubes. The stream flows into the porous straws. Water molecules push through the pores and collect outside the membranes, while the larger particles continue traveling inside the tubes, to be disposed of separately.

The water still needs to be stripped of any viruses that might be adrift in the flow. For this the partially treated stream needs a reverse-osmosis membrane. In one configuration, paperlike sheets of membrane more than a meter long are sandwiched between sheets called spacers. The stack of membranes and spacers is wound up into a cylinder, like a thick roll of wrapping paper. The core of the cylinder is an empty channel where the clean water collects.

As the stream is pushed into one end of the roll, the impurities slide along the spacers and never penetrate the polymer membrane. The water molecules, however, escape through the 0.0001-µm pores and slip into the central channel.

These two steps remove just about everything, but in a third and final step, mercury lamps generate ultraviolet-light rays that penetrate the water. The radiation scrambles the genetic material of any bacteria and other microorganisms that might have slipped through, destroying their ability to reproduce. Now the water is ready for the tap.

The significance of NEWater is much greater than its literal contribution in drops or buckets or liters per person. “NEWater is key to our whole strategy,” Seah says.

Seah is a soft-spoken, dapper man with a face that collapses frequently into a brassy laugh. He’s been with the Public Utilities Board for almost two decades, and he’s seen the NEWater project through to maturity. “The real beauty of NEWater is its multiplying effect,” he explains. What he means is that if the utility recycles 50 percent of its wastewater, Singapore can squeeze one more drop out of every two it desalinates or collects from the sky. “If I can achieve 100 percent recycling, I wouldn’t even need rain,” Seah says.

That’s critical, given how few options Singapore has. Half of the island has already been converted into rainwater catchment areas, and three new reservoirs will soon bring it to two-thirds. The other source of freshwater is Singapore’s one desalination plant, which consumes so much energy it can cover only a fraction of the overall demand.

Consider the details. To remove salt from seawater, Seah says the treatment plant must apply a pressure of about 7 megapascals. To remove impurities from wastewater, he requires less than 1 MPa. That translates directly into the energy cost for the whole plant—more than 4 kilowatt-hours per thousand liters of water for seawater desalination, versus 0.7 kWh for NEWater. “It’s a no-brainer,” says Seah, and his eyes crinkle into a laugh. “Win, win, win!” he says.

[From an article in Popular Science on looking to the sun to desalinate sea water:

Avi Shultz, acting program manager for the Solar Energy Technologies Office at the Department of Energy, explains that, while reverse osmosis is state of the art for desalination, “it’s still not your first choice for generating freshwater, because it is expensive,” Reverse osmosis produces freshwater at a cost of about $1.50 per cubic meter, “which is really a little bit too expensive for it to be widely used,” he says. In the United States, the cost of water averages a little more than $0.50 per cubic meter, though it varies from place to place.Reverse Osmosis is not cheap.]

Asit Biswas, an international water-policy expert who splits his time between the National University of Singapore and the Third World Center for Water Management, in Mexico, sees Singapore as one of the few places where the water authorities agree with his own controversial position—that water scarcity simply does not exist. What does exist, just about everywhere, is bad water management.

The problem, he says, is that people tend to assume that water is like oil or any other fossil fuel and that it behaves according to the same basic economic principles. “But water is not oil,” he says. “Once we use oil, it breaks down into various components. You can’t put it back together.” Water, despite its tendency to evaporate and trickle out of reach, doesn’t change its molecular structure. “There is no limit to how many times water can be reused,” Biswas points out.

That simple fact radically changes the way that water is counted. What’s available to a city or country is not just a matter of how much ice sits in a Himalayan glacier or how much rain falls during monsoon season. Suddenly, Singapore is water rich. The water that falls from the sky may have once washed the streets of Paris or filled Cleopatra’s bathtub. Now it’s augmented with some of the water used by Harry Seah, Asit Biswas, and everybody else in Singapore. The utility isn’t waiting for nature to turn its used water fresh again—it’s letting technology do the job.

Not everyone can be cajoled into drinking recycled urine. In Queensland, Australia, and in San Diego, public opinion has thwarted local utilities’ water-recycling ambitions. But at least three sites in the United States—Scottsdale, Ariz.; Orange County, Calif.; and northern Virginia—purify wastewater and blend it into their drinking water.

In fact, most places reuse water—just without meaning to do so. According to Peter Gleick’s The World’s Water 2002–2003, each drop in the Colorado River is used 17 times. Similarly, residents of London drink water that was discharged from numerous wastewater treatment plants upstream on the Thames.

In Singapore’s case, the deliberate reuse of water has played a prominent role in the country’s development. Seetharam Kallidaikurichi is the director of the Institute of Water Policy at the National University of Singapore, and he argues that Singapore’s water strategy has been the foundation of the country’s economic success in the last 45 years. “The evidence is beginning to emerge,” he says, “that it’s not water among many other things but water as central, the key to unlocking the vicious cycles of deprivation and poverty into economic success and a good quality of life.”

But prioritizing water means using a considerable amount of energy to make it, clean it, and move it. The question is how to optimize the juggle of resources. Because Singapore must import some 290 billion cubic feet of natural gas to run its power plants, it can be said that the country has merely substituted one form of dependence for another.

The consequences of that dependence are starting to hit home. Darren Sun, an associate professor of civil and environmental engineering at Nanyang Technological University, in Singapore, has seen an uptick in interest in his work on energy-efficient membranes. “In most water engineering, people didn’t care about how much energy goes in—until recently. The energy crisis made this a critical issue,” he says. Sun is investigating a membrane design that uses titanium-dioxide nanofibers to filter water and generate electricity simultaneously.

But the research is far from mature, so for now the energy cost will remain high. That’s the price Singapore must pay for a first-rate water supply and a healthy country, says Kallidaikurichi. “You may argue that water here consumes more energy, but the city needs more water, because it’s the city that’s producing more wealth.”

|

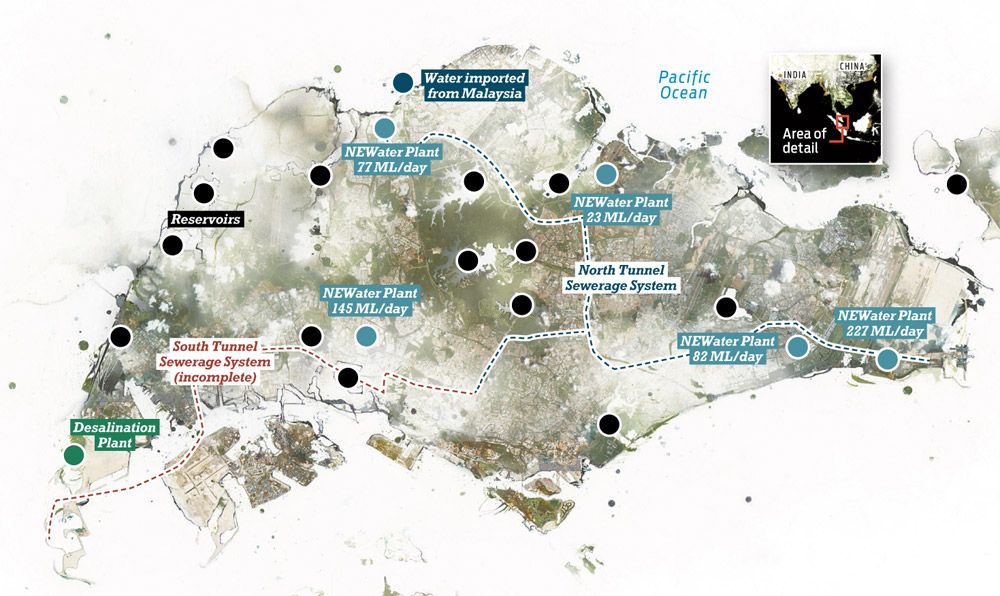

| Not Just Toilets... NEWater plants and reservoirs dot the island, providing an engineered stand-in for the groundwater Singapore lacks. |

The solution to making the trade-off work, say Biswas and Kallidaikurichi, is purely economic: Singapore charges all its customers the marginal cost of water—that is, the cost of producing another liter. For Singapore, that means desalination. So the Public Utilities Board has set the price of water to pay for its energy-intensive operations.

As a result, the utility has enough cash to investigate new technologies. Seah would like to cut the energy needed for desalination by more than half, to 1.5 kWh per thousand liters, and the energy for NEWater to 0.4 kWh from 0.7 kWh.

He’s optimistic. After all, the NEWater processes would have consumed more energy per liter had his engineers not experimented with them. “The technologies came from everywhere, but I think our value is in how we exploit them,” Seah says. “How we put them together. How we wrote the software. How we operate the plants.”

For example, he and his colleagues found a way to introduce a bit of chloramine, a disinfectant, into the membrane-filtration process. That addition prevents the pores from clogging without degrading the membrane material—a challenge that had stymied the industry for some time. Clogged pores mean more pressure to drive the water through, with a larger electricity bill as a result. Similarly, the utility’s engineers have found a way to use less pressure in operating a membrane bioreactor, a machine containing swarms of microorganisms that snack on contaminants in the water. That innovation will soon replace the first filtration step, making NEWater about 20 percent cheaper to produce, Seah says.

Other innovations are likely to trickle out of Singapore’s water sector, as companies and academics seek to profit from the water utility’s interest in innovation. For example, researchers under Say Leong Ong, acting head of the environmental sciences and engineering division at the National University of Singapore, are figuring out the mechanisms used by mangrove trees and tilapia fish to process the salt in seawater, with the hope of one day designing membranes that mimic nature.

Ultimately, Singapore will have true water security only if it can reduce its dependence on imported energy. A civilization’s surplus energy, arising from its trade and technological prowess, is what allows an economy to shift investment away from life-critical needs such as water to education, art, and a rich civic life. An energy-secure water sector, then, will be a major question for the next 50 years of the tiny island’s nationhood.

This article originally appeared in print as “Wizards of the Water Cycle.”

No comments:

Post a Comment